Excellence

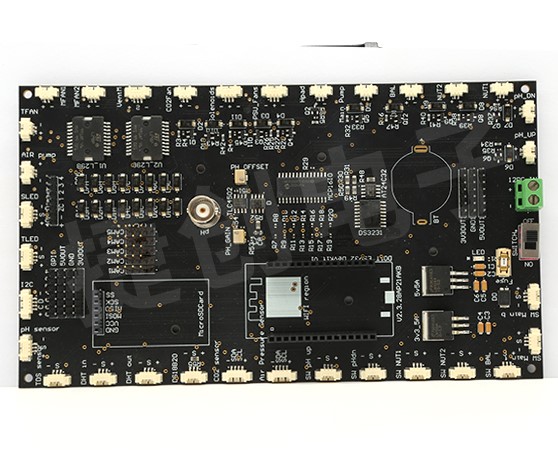

GV Techno Solutions is a leading provider of technology solutions.

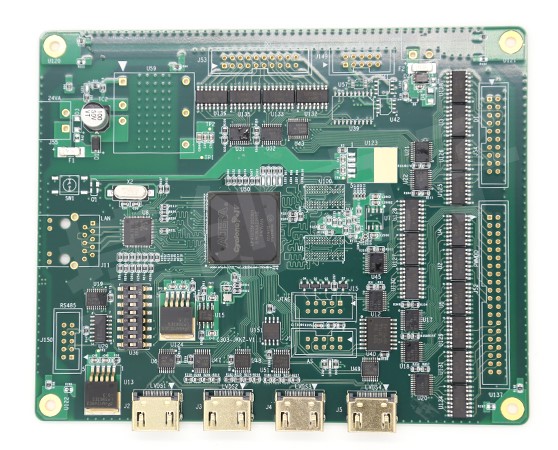

For over two decades, GV Techno Solutions has been at the forefront of embedded technology innovation, delivering cutting-edge solutions to clients across diverse industries.

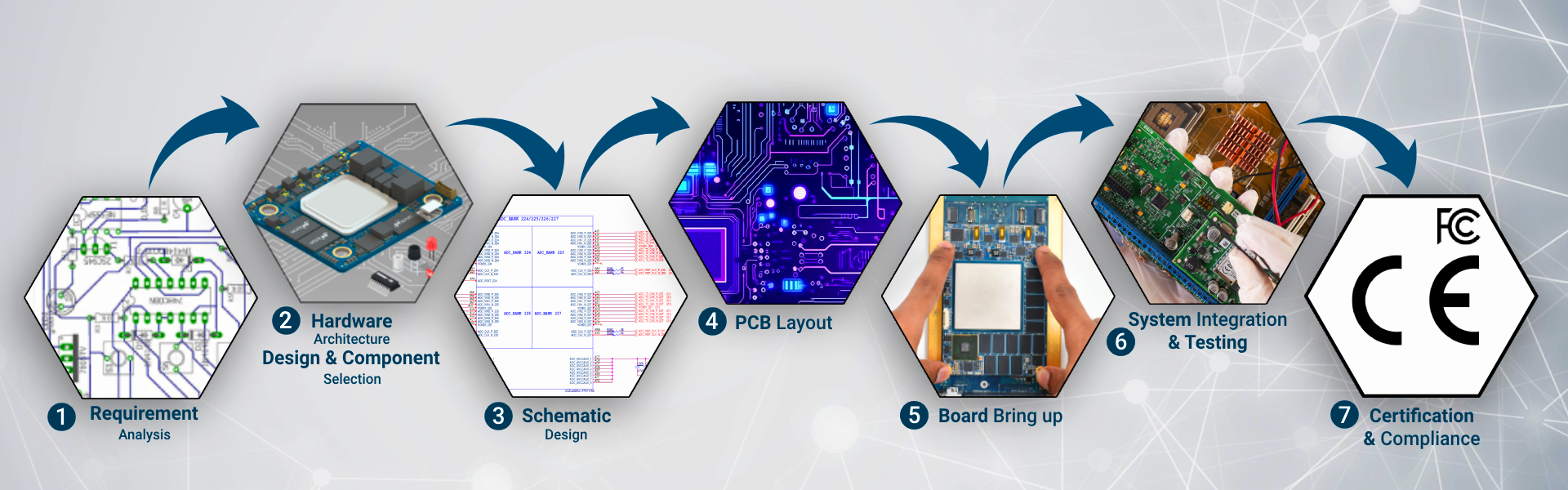

Our journey began with a vision to revolutionize the embedded systems landscape. Since then, we've continuously evolved, adapting to technological advancements while maintaining our commitment to quality and excellence. Our extensive experience has enabled us to develop deep expertise in complex system design, hardware engineering, and software development.

Today, we stand as a trusted partner for businesses worldwide, offering end-to-end solutions from concept to deployment. Our team of skilled engineers and technicians brings together decades of collective experience to solve the most challenging technological problems.

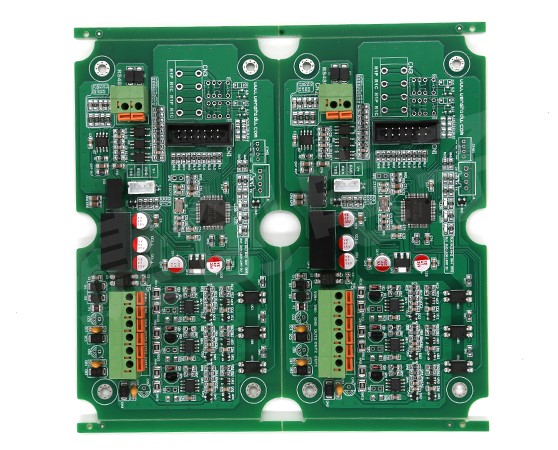

Quality Assurance

ISO 9001:2015 certified with rigorous testing protocols

Innovation Focus

Cutting-edge solutions with latest technological advances

Recognized by Our Clients

Appreciated by Leading Defence and Industrial Automotive Clients